Innovative Cooling Technologies Powered by Tungsten-Copper Heat Sink Designs

In recent years, the demand for efficient cooling technologies has surged dramatically, driven by the rapid advancement of electronic devices and high-performance computing systems. One of the most promising developments in this field is the use of tungsten-copper heat sink designs, which have emerged as a revolutionary solution to manage thermal challenges effectively.

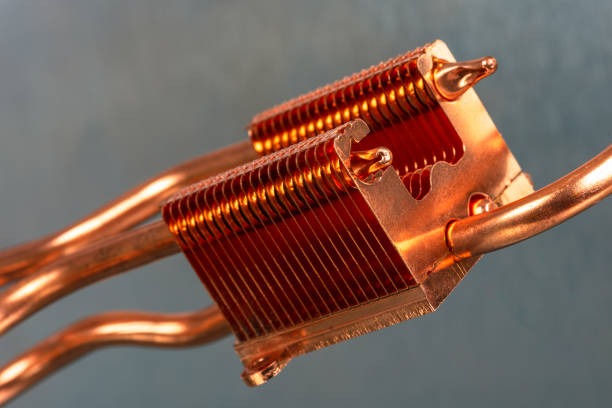

Tungsten-copper composites are renowned for their exceptional thermal and electrical conductivity properties. This unique combination arises from tungsten’s high melting point and strength paired with copper’s superior thermal conductivity. By integrating these materials into heat sink designs, engineers have been able to create solutions that efficiently dissipate heat generated by electronic components, thereby enhancing performance and reliability.

The innovation behind tungsten-copper heat sinks lies in their ability to maintain structural integrity under extreme temperatures while offering excellent thermal management capabilities. These heat sinks are particularly advantageous in applications where traditional materials might fail due to excessive heat or mechanical stress. For instance, they are increasingly being employed in aerospace technology, telecommunications equipment, and advanced computing systems where maintaining optimal operating temperatures is critical.

One key benefit of using tungsten-copper composites is their adaptability to various design requirements. They can be manufactured into complex shapes and sizes tailored specifically for different applications https://amt-mat.com/understanding-tungsten-copper-heat-sinks/ without compromising on performance. This flexibility allows engineers to integrate them seamlessly into existing systems or develop new configurations that maximize cooling efficiency.

Moreover, tungsten-copper heat sinks contribute significantly to energy efficiency efforts across industries. By effectively managing waste heat, they help reduce the overall power consumption of devices and systems—an essential factor as industries strive towards greener practices amid increasing environmental concerns.

Another notable advantage is their longevity compared to conventional cooling solutions. Tungsten-copper composites exhibit remarkable resistance against wear and corrosion even when subjected to harsh environments over extended periods. This durability ensures that devices equipped with these innovative heat sinks require less frequent maintenance or replacement parts—a crucial consideration for reducing operational costs in industrial settings.

As technology continues its relentless march forward with more powerful processors and compact device architectures becoming commonplace, the role of advanced cooling solutions like tungsten-copper heat sinks becomes ever more vital. Researchers are continually exploring ways to enhance these composites further through nanotechnology advancements or hybrid material integrations aimed at pushing boundaries even further regarding efficiency gains.

In conclusion, innovative cooling technologies powered by tungsten-copper heat sink designs represent a significant leap forward in addressing modern-day thermal management challenges across various sectors globally—from consumer electronics all way up through heavy industry applications—thereby ensuring sustained progress toward achieving higher levels performance coupled alongside sustainability goals within our rapidly evolving technological landscape today!